We engineered tomorrow for

75%

Reduction in components

0.5

Working hours saved per part

20%

Cost down

Project Objective

DB are a time critical entity, working to short windows in which to refit and repair heavy rolling stock. Having worked side-by-side with the DB team for some time, GMS understood the challenges they faced and wanted to assist in tackling them head on.

With welders in high demand and short supply across the industry, it was no surprise that the major headache of the day was related to the volume of welding that fabricators required. GMS’s solution was simple; the less time spent welding, the quicker product could get out. All that was needed was a suitable candidate…

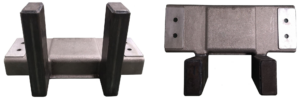

Touring the DB site the FCA Drawhook System Guide was earmarked as a perfect candidate for DFM (design-for-manufacture) refinement, a 13 part unit fabricated from a mixture of plate and C / hollow section. Not only did DB have to order the individual subcomponents themselves, but also the raw material stock that were cut and prepared the numerous parts from, after which the components were extensively welded and the unit heat treated.

So how could GMS best help?

Original fabricated design and BOM

Project Method

Having inspected the technical documentation, it was apparent that this assembly could yield improved efficiencies as a cast-machined part.

Reviewing with our manufacturing partner, GMS was able to provide a concept model of the proposed casting for analysis by DB engineering department, along with suggested adjustments to make the assembly more streamlined for the casting process and increase performance.

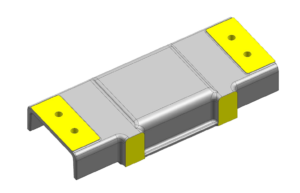

The model shown below demonstrates where previous cut parts are now incorporated into the casting, this includes the underside bottom plate. To ensure correct fit with mating parts (i.e. guide posts) these yellow faces are machined flat.

GMS proposed design

Following DB approval GMS began the tooling and sample production process. Supplying samples along with FAI documents, DB were thrilled at the time saved both in production and in fitment, and approved it within a week.

Project Outcome

Through patient consideration of customer challenges and application of its DFM expertise, GMS was able to work closely with DB to provide a casting/fabrication solution that delivered the following outcomes:

- reduction in inventory stock holding

- reduction in raw stock holding

- reduction in number of stock lines

- reduction in issuing of purchase orders

- less movement of parts

- improved vibrational resistance

- increased strength

- increased capacity

- improved throughput

- (most importantly) cost savings

GMS assisted design

GMS are a very reliable supplier, I can rely on being informed, prices and overall delivery quality from GMS. Due to the nature of our business knowing the most accurate information is essential, GMS provide me with that on a regular basis, this allows me to be able to inform our customers and stakeholders in good time. The technical knowledge of the staff at GMS is excellent, I know I can send an enquiry into GMS and it will be looked into in detail, this is reflected in any technical FAI process with GMS has shown no failures, all parts are supplied as detailed and discussed.

T. Harris - Procurement Manager